Understanding Predetermined Overhead Rate: A Beginner’s Guide

Analyzing overhead rates by department in this manner helps identify problem areas and opportunities to improve profitability. Knowing the overhead cost per unit allows the business to set competitive pricing while still predetermined overhead rate covering their indirect expenses. We’ll outline the basic formulas used to calculate different types of overhead rates and provide overhead cost examples. Rather than lump overhead costs into one expense account, businesses should allocate fixed and variable overhead to departments.

Accounting Ratios

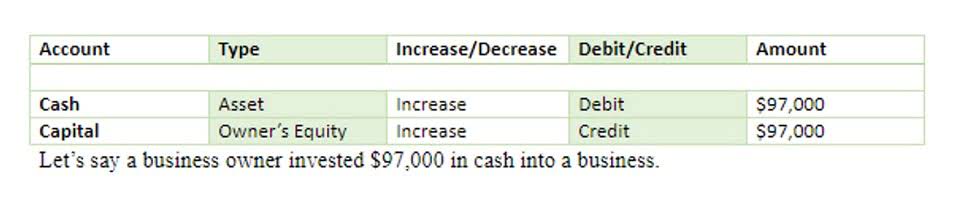

In order to estimate the predetermined overhead rate it is first necessary to to decide on an activity base on which to apply overhead costs to a product. In larger companies, each department in which different production processes take place usually computes its own predetermined overhead rate. The formula for a predetermined overhead rate is expressed as a ratio of the estimated amount of manufacturing overhead to be incurred in a period to the estimated activity base for the period. Take, for instance, a manufacturing company that produces gadgets; the production process of the gadgets would require raw material inputs and direct labor.

Sales and production decisions based on this rate could be faulty

In addition while manufacturing overheads might vary seasonally throughout the year, the use of a constant predetermined rate avoids a similar variation in unit product cost. If the job in work in process has recorded actual material costs of 4,640 for the accounting period then the predetermined overhead applied to the job is calculated as follows. If a job in work in process has recorded actual machine hours of 140 for the accounting period then the predetermined overhead applied to the job is calculated as follows. The predetermined overhead rate formula can be used to balance expenses with production costs and sales. For businesses in manufacturing, establishing and monitoring an overhead rate can help keep expenses proportional to production volumes and sales. It can help manufacturers know when to review their spending more closely, in order to protect their business’s profit margins.

Understanding Write-Offs: What They Mean and How They Work

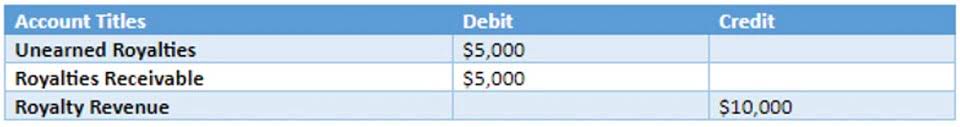

Using the Solo product as an example, 150,000 units are sold at a price of $20 per unit resulting in sales of $3,000,000. The cost of goods sold consists of direct materials of $3.50 per unit, direct labor of $10 per unit, and manufacturing overhead of $5.00 per unit. With 150,000 units, the direct material cost is $525,000; the direct labor cost is $1,500,000; and the manufacturing overhead applied is $750,000 for a total Cost of Goods Sold of $2,775,000. This $4 per hour overhead rate would then be applied to the number of direct labor hours for each job to allocate overhead costs. If the predetermined overhead rate calculated is nowhere close to being accurate, the decisions based on this rate will definitely be inaccurate, too. That is, if the predetermined overhead rate turns out to be inaccurate and the sales and production decisions are made based on this rate, then the decisions will be faulty.

Choosing an Allocation Base

- Accurately calculating overhead rates is important for determining the full cost of a product and appropriately pricing goods and services.

- Once costs are broken down, small businesses can assess if any categories are excessive.

- Using small business accounting software centralizes overhead tracking and analysis.

- Overhead costs are then allocated to production according to the use of that activity, such as the number of machine setups needed.

- This comparison can be used to monitor or predict expenses for the next project (or fiscal year).

- This activity base is often direct labor hours, direct labor costs, or machine hours.

Once a company has determined the overhead, it must establish how to allocate the cost. This allocation can come in the form of the traditional overhead allocation method or activity-based costing.. The formula seems simple – total overhead costs divided by an allocation base like direct labor hours. However, accurately calculating overhead rates involves breaking down costs and choosing the right allocation base. A predetermined overhead rate is calculated at the start of the accounting period by dividing the estimated manufacturing overhead by the estimated activity base. The predetermined overhead rate is then applied to production to facilitate determining a standard cost for a bookkeeping product.

- This is why a predetermined overhead rate is computed to allocate the overhead costs to the production output in order to determine a cost for a product.

- As you’ve learned, understanding the cost needed to manufacture a product is critical to making many management decisions (Figure 6.2).

- In this article, we will discuss the formula for predetermined overhead rate and how to calculate it.

- Once a company has determined the overhead, it must establish how to allocate the cost.

- By understanding its mechanics, businesses can improve financial planning and maintain accurate product costing.

Build & Forecast IS, BS, CF from Scratch.

The predetermined overhead rate is, therefore, usually used for contract bidding, product pricing, and allocation of resources within a company, based on each department’s utilization of resources. Before the beginning of any accounting year, it is determined to estimate the level of activity and the amount of overhead required to allocate the same. At a later stage, when the actual expenses are known, the difference between that allocated overhead and the actual expense is adjusted. Finally, if the business uses material costs as the activity base and the estimated material costs for the year is 160,000 then the predetermined manufacturing overhead rate is calculated as follows.

This activity base is often direct labor hours, direct labor costs, or machine hours. Once a company determines the overhead rate, it determines the overhead rate per unit and adds the overhead per unit cost to the direct material and direct labor costs for the product to find the total cost. The predetermined overhead rate is calculated by dividing the estimated manufacturing overhead by the estimated activity base (direct labor hours, direct labor dollars, or machine hours). For instance, if the activity base is machine hours, you calculate predetermined overhead rate by dividing the overhead costs by the estimated number of machine hours. This is calculated at the start of the accounting period and applied to production to facilitate determining a standard cost for a product.

In summary, overhead rates have a sizable impact on a company’s key financial statements and decisions. Investing time into overhead analysis and accurate calculation of rates leads to better accounting and superior business management. The estimated manufacturing overhead cost applied to the job during the accounting period will be 1,450. The estimated manufacturing overhead cost applied to the job during the accounting period will be 1,600. The estimated manufacturing overhead cost applied to the job during the accounting period will be 1,494.

Find the talent you need to grow your business

The controller of the Gertrude Radio Company wants to develop a predetermined overhead rate, which she can use to apply overhead more quickly in each reporting period, thereby allowing for a faster closing AI in Accounting process. A later analysis reveals that the actual amount that should have been assigned to inventory is $48,000, so the $2,000 difference is charged to the cost of goods sold. For example, the total direct labor hours estimated for the solo product is 350,000 direct labor hours. With $2.00 of overhead per direct hour, the Solo product is estimated to have $700,000 of overhead applied. When the $700,000 of overhead applied is divided by the estimated production of 140,000 units of the Solo product, the estimated overhead per product for the Solo product is $5.00 per unit.